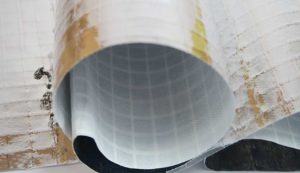

Composite films made of aluminium, PE and PET, plastics

Aluminium as a composite film in combination with plastics is a functional and visually enhanced product that is now an indispensable part of any industry.

We supply the processing industry, trade, food and pharmaceutical manufacturers, the construction industry and many other sectors with all types of composite films made of aluminium, PE and PET.

Highly functional and further refined laminated films are solutions tailored to your industry. The spectrum ranges from laminated film as a base material for your packaging to film as a base material for building insulation or for use in science and research, for example.

Laminating (lamination) and coating (extrusion)

Common processes in the production of composite films are lamination (laminating) and coating (extrusion)

Lamination types:

- Wet lamination

- Dry laminating

- Wax lamination

- Solvent-based lamination

- Solvent-free laminating

Coating types:

Lacquering is the most common type of coating. High-gloss surfaces can be realised here. You can also obtain laminated films that are functionally coated in such a way that they offer optimum flavour protection or guarantee barrier protection, for example.

There are numerous possibilities for functional and visual refinement and we can realise them to suit your needs. Benefit from our decades of experience in this field.

Composite films available in these dimensions:

- 8-10 mm

- 10-50 mm

- 50-100 mm

- 100-200 mm

- 200-300 mm

- 300-400 mm

- 400-500 mm

- 500-750 mm

- 750-1000 mm

- 1000-1300 mm

- 1300-1600 mm

- 1600-1900 mm

- 1900-2100 mm

- from 2100 mm

Composite film types

Different compositions of the basic materials of a composite film create the desired functions and properties:

| Composition | Purpose | Surface |

|---|---|---|

| PET + aluminium + PE | Packaging | Print up to 10 colours |

| PET + aluminium + PP | Packaging | Print up to 10 colours |

| PET met + PE | Packaging | Print up to 10 colours |

| PET met + PP | Packaging | Print up to 10 colours |

| PET aluminium + PP | Cables | Imprint possible |

| PET + aluminium + HDPE | Bulk packaging | Print up to 10 colours |

| Paper + aluminium + PE | Packaging | Print up to 10 colours |

| Paper + PE | Packaging | Print up to 10 colours |

| Aluminium + PE | Insulation | Protective lacquer application possible |

| Aluminium + PET | Insulation | Protective lacquer application possible |

| PET + aluminium + PET | Insulation, cable | Printing possible |

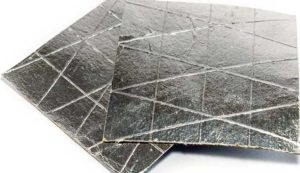

Clutch and tissue:

Insulation manufacturers rely on our company's aluminium and composite films. One of our main areas of expertise is the customised provision of functional composite films with scrims and fabrics:

| Composition | Purpose | Surface |

|---|---|---|

| PET+cloth+aluminium+PE | Insulation, bulk packaging | Print up to 10 colours |

| PET+cloth+aluminium+PET | Insulation, bulk packaging | Print up to 10 colours |

| PET+Aluminium+Fabric | Insulation, bulk packaging | Print up to 10 colours |

| PETmet+fabric | Insulation, bulk packaging | Print up to 10 colours |

Composite film type Properties

Polyamide (PA)

- High strength

- Mechanically resilient

- Very good barrier function

- Barrier function decreases with high humidity

- Resistant to cold and heat

- Insensitive to water

- Thermoformable and stretchable

Polypropylene (PP)

- High mechanical strength

- Permeable to oxygen

- Insensitive to water

- Good water vapour barrier

- Only moderately heat-resistant

Polyvinyl chloride (PVC)

- High rigidity

- Good thermoformability

- Heat and cold resistant

Cellophane

- Good barrier function with low humidity

- Low mechanical strength

- Not weather-resistant

Polyester (oPET)

- Resistant to mechanical stress

- Heat and cold resistant

- Insensitive to water

- Good barrier properties

Typical print carrier films

- Polyester film (PET)

- Polypropylene film (PP)

- Polyamide film (PA)

Typical barrier films

- Aluminium foils

- Metallised films ( PET-MET)

- Vaporised films

- EVOH

- PVDC

Typical sealing films

- PE films

- PP films

Your supplier of laminated films

We see ourselves as experts and suppliers of laminated films to the processing industry. Do you have production-related fluctuations in the quantity required or do you need customised products?

We are also happy to supply you with smaller quantities, customised for your company, as well as custom-made products and prototypes.

We would be happy to provide you with samples or advise you on product development and solutions in laminated film. Get in touch with us!